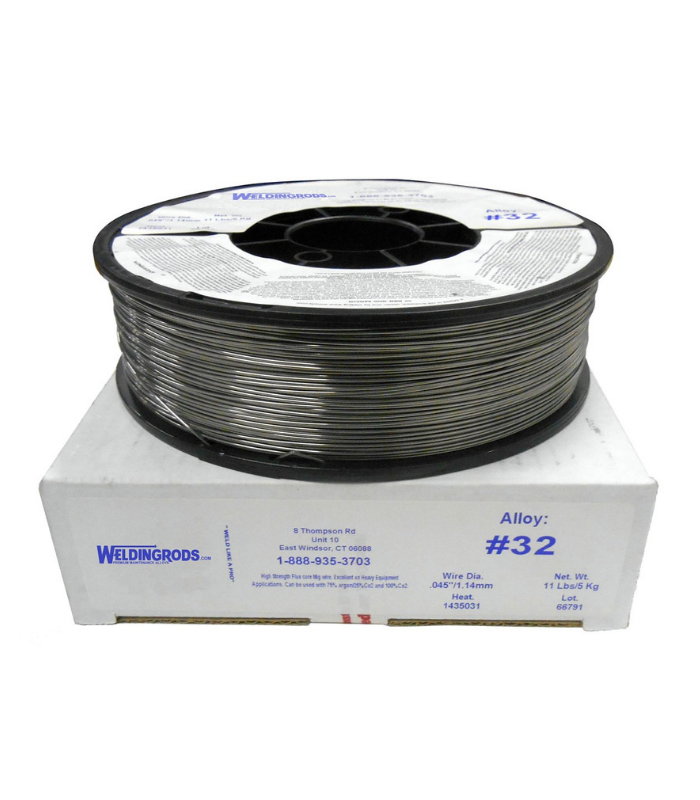

Our #32 fluxed core Mig Wire for Heavy Equipment is a high strength, all position, maintenance wire. It’s used primarily for joining of heavy equipment. Buckets, dump truck bodies, frames, and booms with varying amounts of vibration. #32 is also excellent for building up of wear surfaces before applying hardface. # 32 is excellent out of position because the welds fast freeze, very smooth running no porosity welds, easy slag removal.

- We are no longer fulfilling online orders. Please contact us at 888-935-3703.

SaleHot

Previous product

Back to products

12 Hardfacing Electrode for Severe Wear

$124.40 – $652.05

Next product

6 Mig Wire for Build-Up and Joining

$155.40 – $158.90

32 Mig Wire for Heavy Equipment

$44.58 – $160.30

Our #32 fluxed core Mig Wire for Heavy Equipment is a high strength, all position, maintenance wire. It’s used primarily for joining of heavy equipment. The smoothest running fluxed core mig wire available.

SKU: N/A

Categories: Construction, Demolition, Maintenance, Recycling

Tags: Mig & Fluxed cored Welding Wire, Mig Wire

Reviews (0)

Be the first to review “32 Mig Wire for Heavy Equipment” Cancel reply

This site uses Akismet to reduce spam. Learn how your comment data is processed.

Related products

3100 Welding Rod for Aluminum

$230.00 – $379.00

909 Welding Rod for Rusty Equipment

$27.50 – $133.35

HSP90 Welding Putty

$74.60 – $170.55

770 Welding Rod for Cast Iron

$77.00 – $489.90

770 Welding Rod for Cast Iron is excellent for welding in deep recesses or on non-conductive coating. Creates very strong joints on cast & steel applications. Excellent for many different applications :

Pump bodies, Compressors, Machine frames, Casting defects, Lathes, Pulleys, Dies, Levers, Gears, Generators, Flanges, Tables and engine blocks.

Weldingrods.com 770 Cast iron is fully machinable and has a tensile strength of up to 55,000psi.

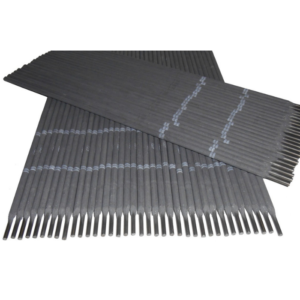

12 Hardfacing Electrode for Severe Wear

$124.40 – $652.05

9 Tubular Chrome Carbide Hardface

$154.14 – $580.44

Our 9 Welding Rod for Large Area Hardfacing is our tubular chrome carbide product. It's great for applying out of position in large areas that need protecting.

Watch the video to the left. Dave Miller explains #9 in depth.

Watch our demo video on Facebook

Super 32 Extra Low-Hydrogen

$25.00 – $29.40

WR1247 SHEAR HARDFACE

$615.49

WR1247 Is made to give maximum wear to the shear while still allowing machinability to the base. Deposits reach maximum hardness as deposited. And can be tempered to reduce stress. Weld deposit is highly shock resistant and resistant to heat checking. Apply a maximum of two passes of WR1247 only. Use WR#32 first if Build-up is needed.

Available in 1/16 diameter 25lb spool.

Reviews

There are no reviews yet.