Online Store is Closed. Thank You for your Business.

127 Alloy Steel Welding Rod for Construction Repair

Do you purchase 7018?

Try our 127 low-hydrogen welding rods. Made in the USA.

On Sale Now 50lb Boxes

The smoothest running extra-low hydrogen welding electrode. Excellent out of position, best welding rod for all types of construction equipment. Extra-low hydrogen electrode for high resistance welding.770 Welding Rod for Cast Iron

770 Welding Rod for Cast Iron is excellent for welding in deep recesses or on non-conductive coating. Creates very strong joints on cast & steel applications. Excellent for many different applications :

Pump bodies, Compressors, Machine frames, Casting defects, Lathes, Pulleys, Dies, Levers, Gears, Generators, Flanges, Tables and engine blocks.

Weldingrods.com 770 Cast iron is fully machinable and has a tensile strength of up to 55,000psi.

MOST POPULAR

FEATURED PRODUCTS

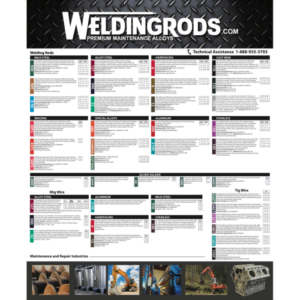

Welding Rod Chart

Weldingrods.com Welding Rod Wall Chart offers an easy way to compare our premium welding alloys and end-uses. Print out a copy and hang in your welding shop, today!

Must order free wallchart download through the shopping cart.

Order Free Hard Copy Of the Weldingrods.com wall chart and (Just Pay Shipping).

9 Tubular Chrome Carbide Hardface

Our 9 Welding Rod for Large Area Hardfacing is our tubular chrome carbide product. It's great for applying out of position in large areas that need protecting.

Watch the video to the left. Dave Miller explains #9 in depth.

Watch our demo video on Facebook

INDUSTRY APPLICATIONS

Which Product Is Right For Me?

I WANT TO...

REPAIR MADE EASY

Welcome to Weldingrods.com

At Weldingrods.com, we carry both Welding Rods and Mig Wires to complete a variety of maintenance applications. All of our products are in stock & ready to ship. Place your order online, today!

Need a Consultation? Contact Us 24/7

With over 30 years of welding experience, we can help you with your next project.